Repetitive Digit Design and Analysis

What is this?

As a self-guided research project in collaboration with the University of Victoria, engineering students can investigate a possible application of concepts being studied for their economic viability as a product. This project allows for many aspects of practical design for use by consumers to be experienced without the only requirement being to learn something new. From this perspective, the analysis of 3 different design prototypes were quantified and compared for their possible use as a consumer product with applications in puppetry, rapid prototyping and artistry.

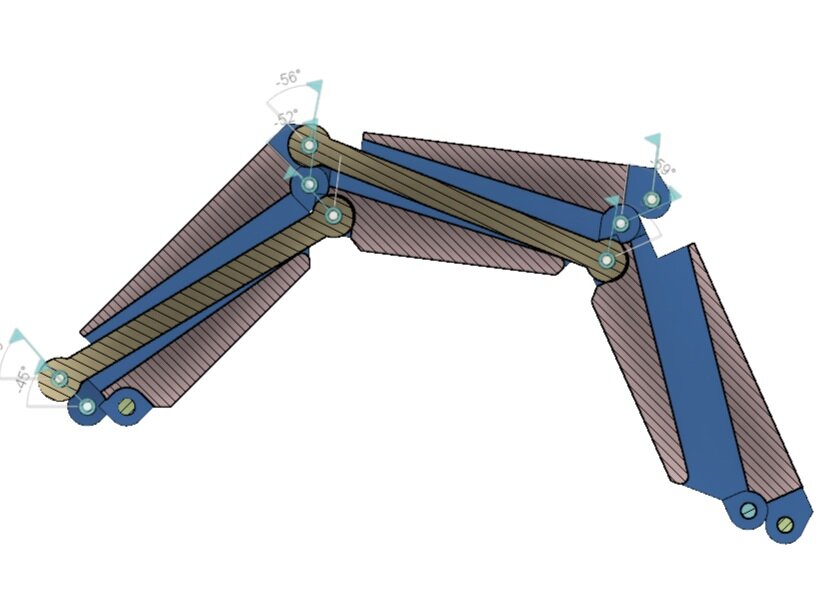

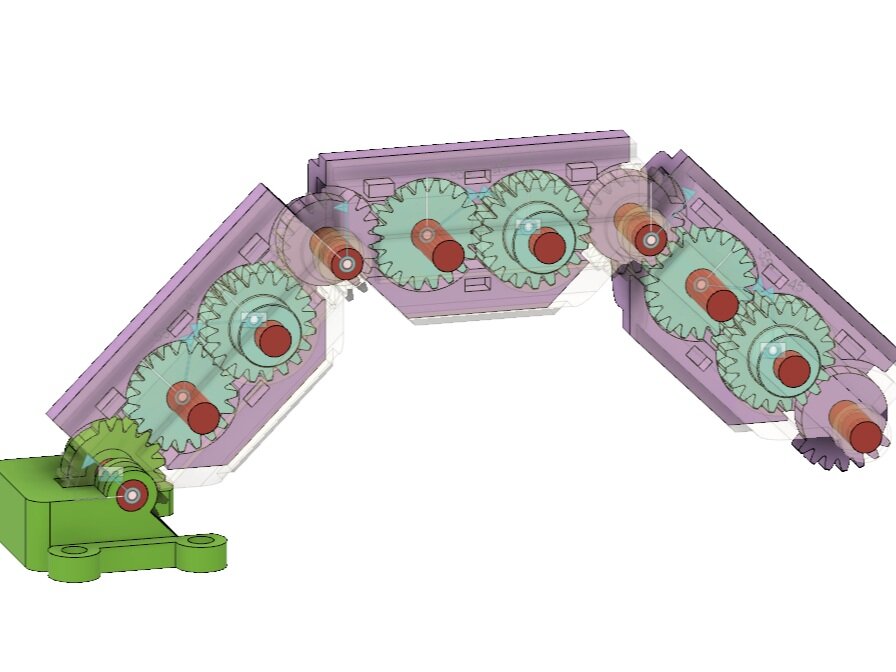

All 3 of these designs meet the self-imposed required criteria that:

The articulating assembly is made of a repeating mechanism wherein each digit can be located at any position without bias

The range of motion for each unit is 90 degrees around an anchor pin

Each repeating assembly must output 90 degrees of motion to the next connected sub-unit

There is no theoretical limit to the number of allowable sub-units

Each of these designs had the further physical limitation for actually 3D printing them for testing. In the planetary gear prototype, the 14-tooth gears are based on the available parts at McMaster Carr. However they were printed for convenience, with the added challenge of painstaking prep (not exaggerating, it took forever).